Fixing Industrial Refrigeration Repair Service: Strategies for Quick and Effective Fixes

Understanding the usual problems that afflict commercial refrigeration systems and having a toolkit of diagnostic methods at your disposal can make all the difference in promptly recognizing and treating problems. As we browse with the complexities of fixing commercial refrigeration fixing, we will discover the essential approaches for resolving issues successfully, ensuring that businesses can maintain optimal cooling efficiency and minimize downtime.

Typical Business Refrigeration Issues

Commercial refrigeration systems frequently experience a variety of functional issues that can disrupt their performance and performance. One widespread concern is incorrect temperature level control, which can cause food spoilage and waste otherwise quickly dealt with. This issue may originate from issues with the thermostat, evaporator fan, or condenser coils, needing complete evaluation to identify the source. An additional typical issue is poor airflow, typically triggered by clogs in the vents or a malfunctioning follower. Poor air flow can cause temperature level disparities within the fridge or fridge freezer, influencing the quality and safety of saved items.

Moreover, cooling agent leakages posture a substantial worry as they not only impact the air conditioning capability of the system but additionally add to environmental damage. Finding and repairing leakages promptly is critical to stop additional damage and guarantee compliance with regulations. Additionally, filthy condenser coils can hamper heat transfer, requiring the system to work more difficult and consume even more power. Normal cleaning and maintenance can assist avoid this concern and prolong the life-span of the refrigeration system.

Analysis Devices and Methods

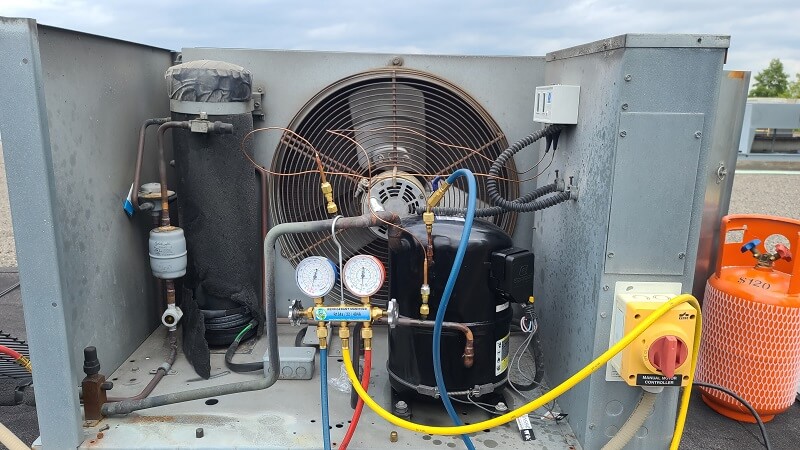

Reliable troubleshooting of industrial refrigeration systems relies heavily on making use of specialized diagnostic tools and methods to identify and solve underlying problems successfully - commercial refrigeration repair. Additionally, leak detection devices like digital leakage detectors or ultraviolet color packages are crucial for finding refrigerant leakages that can lead to system inadequacies.

Information loggers can be employed to monitor system efficiency over time and detect patterns that might indicate reoccuring troubles. By combining these analysis devices and techniques, technicians can successfully troubleshoot business refrigeration systems and offer precise and fast fixings, decreasing downtime and making sure optimal system efficiency.

Quick Solutions for Refrigeration Problems

When faced with refrigeration troubles, service technicians can carry out fast repairs to attend to common problems swiftly and efficiently. If the refrigeration system is not cooling properly, inspecting and adjusting the thermostat settings might give a fast service prior to even more comprehensive troubleshooting is required. By executing these fast repairs, technicians can resolve usual refrigeration troubles efficiently and keep industrial refrigeration systems running smoothly.

Preventative Upkeep Tips

Carrying out an aggressive upkeep routine is critical for making certain the longevity and optimum efficiency of industrial refrigeration systems. Routine upkeep not just assists prevent expensive break downs yet also makes sure that the tools runs efficiently, saving power and minimizing total operating prices. Right here are some preventative upkeep ideas to maintain industrial refrigeration systems running efficiently:

Examine and Change Filters: Filthy filters can restrict airflow, making the system job harder and possibly creating damage. Inspect and replace filters on a regular basis to protect against problems.

Inspect Seals and Gaskets: Leaky seals and gaskets can cause temperature variations and energy wastefulness. Changing and evaluating harmed seals can aid keep constant temperature levels.

Specialist Support and Services

To maintain the ideal performance achieved through routine preventative upkeep, looking for expert assistance and services for business refrigeration systems is crucial. Professional service technicians have the proficiency and specialized knowledge required to detect and attend to complicated issues successfully. When encountering difficult refrigeration troubles, depending on specialist support can conserve both money and time over time.

Specialist solutions supply advantages such as accessibility to sophisticated devices and equipment, making certain that fixings are executed successfully. In addition, professionals are trained to abide by market regulations and safety criteria, minimizing the risk of accidents and guaranteeing compliance with legal demands.

Verdict

Finally, repairing commercial refrigeration fixing calls for a methodical approach to determining typical issues, utilizing diagnostic tools and methods, carrying out fast fixes, and focusing on preventative upkeep. Specialist support and solutions may be required for more complex troubles - commercial refrigeration repair. By following these check these guys out methods, companies can ensure their refrigeration systems operate efficiently and effectively, minimizing downtime and potential losses

Comprehending the typical issues that afflict commercial refrigeration systems and having a toolkit of analysis techniques at your disposal can make all the difference in swiftly recognizing and fixing problems.Effective troubleshooting of commercial refrigeration systems counts greatly on using specialized analysis devices and methods to recognize and settle underlying issues effectively. By incorporating these diagnostic devices and methods, technicians can efficiently repair commercial refrigeration systems and offer fast and specific repairs, reducing downtime and making sure ideal system efficiency.

By carrying out these quick solutions, technicians can deal with common refrigeration problems efficiently and maintain commercial refrigeration systems running efficiently.

In addition, professional assistance can assist extend the life-span of commercial refrigeration systems by identifying possible concerns before read the full info here they rise.

Comments on “How to Conserve Money with Professional Commercial Refrigerator Repair Solutions”